In packaging, small details make a big difference — and one of the most important details is understanding the length width height of a box. These three numbers affect everything from how your product fits in the box to how much you’ll pay for shipping.

If you’ve ever struggled to measure a box correctly or wondered what order to list dimensions, you’re not alone. That’s why Custom Packaging Pro created this guide — to help businesses avoid costly packaging errors and ship smarter.

What Do Length, Width, and Height Really Mean?

These terms describe the three-dimensional measurements of a physical object, such as a cardboard box or product container.

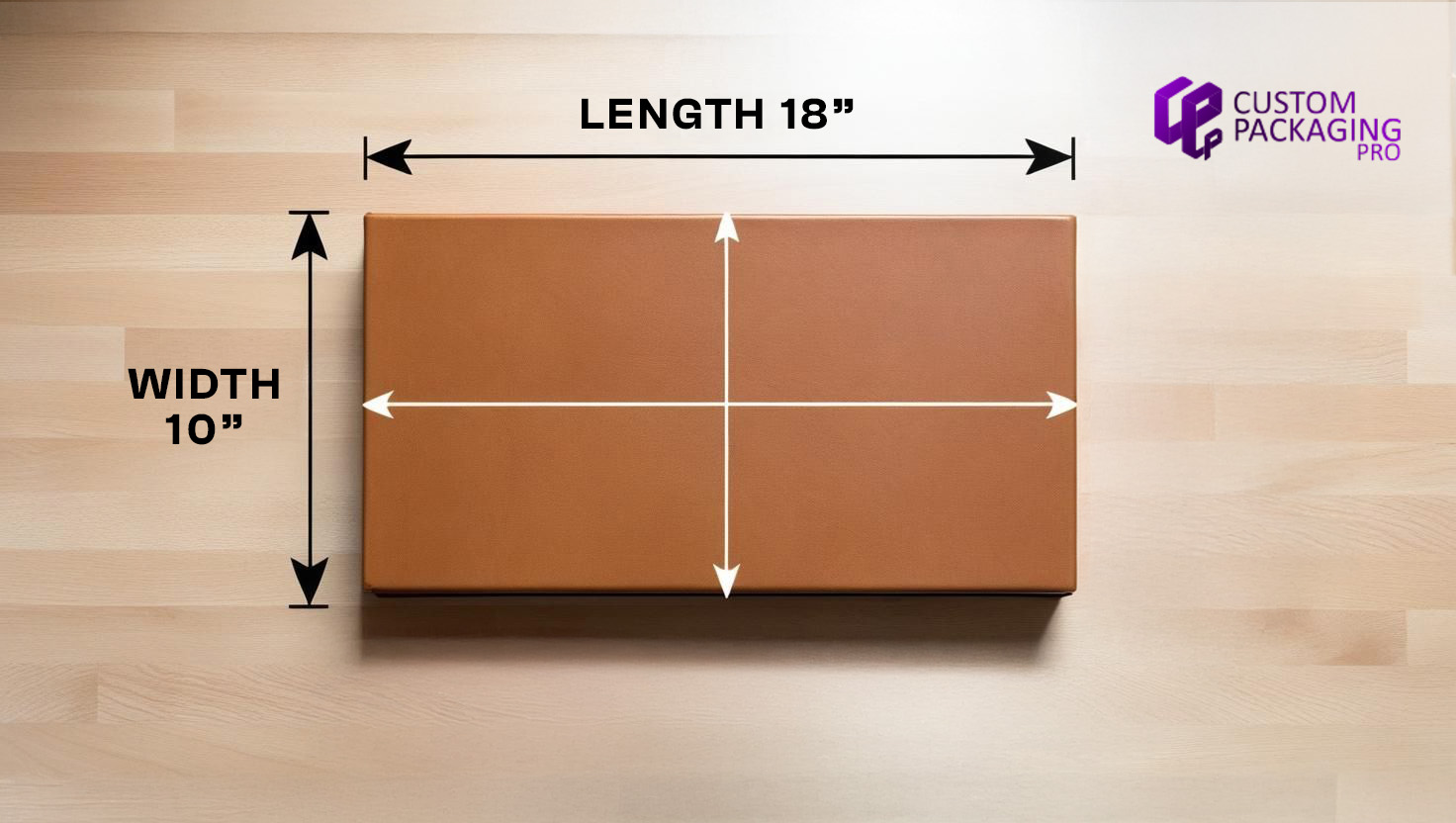

📏 Length. This is the longest side of the base when the box is placed normally.

📏 Width. The shorter side of the base, perpendicular to the length.

📏 Height. The vertical measurement from the base to the top.

So, a box listed as 10 × 6 × 4 inches means:

- 10 inches long (L)

- 6 inches wide (W)

- 4 inches high (H)

This format — Length × Width × Height — is the standard way dimensions are listed, and it’s the format used by shipping companies, packaging suppliers, and manufacturers alike.

Why Is the Order of Dimensions Important?

If you reverse these numbers — for example, 4 × 10 × 6 — you end up with a completely different box. That’s why confirming the order of dimensions matters, especially when you’re working with custom packaging.

At Custom Packaging Pro, we always ask clients to use the L × W × H format, unless otherwise specified. It avoids confusion and ensures the product fits perfectly.

How to Measure Length, Width, and Height Accurately

Knowing the terms is one thing — but how do you measure a real box in practice?

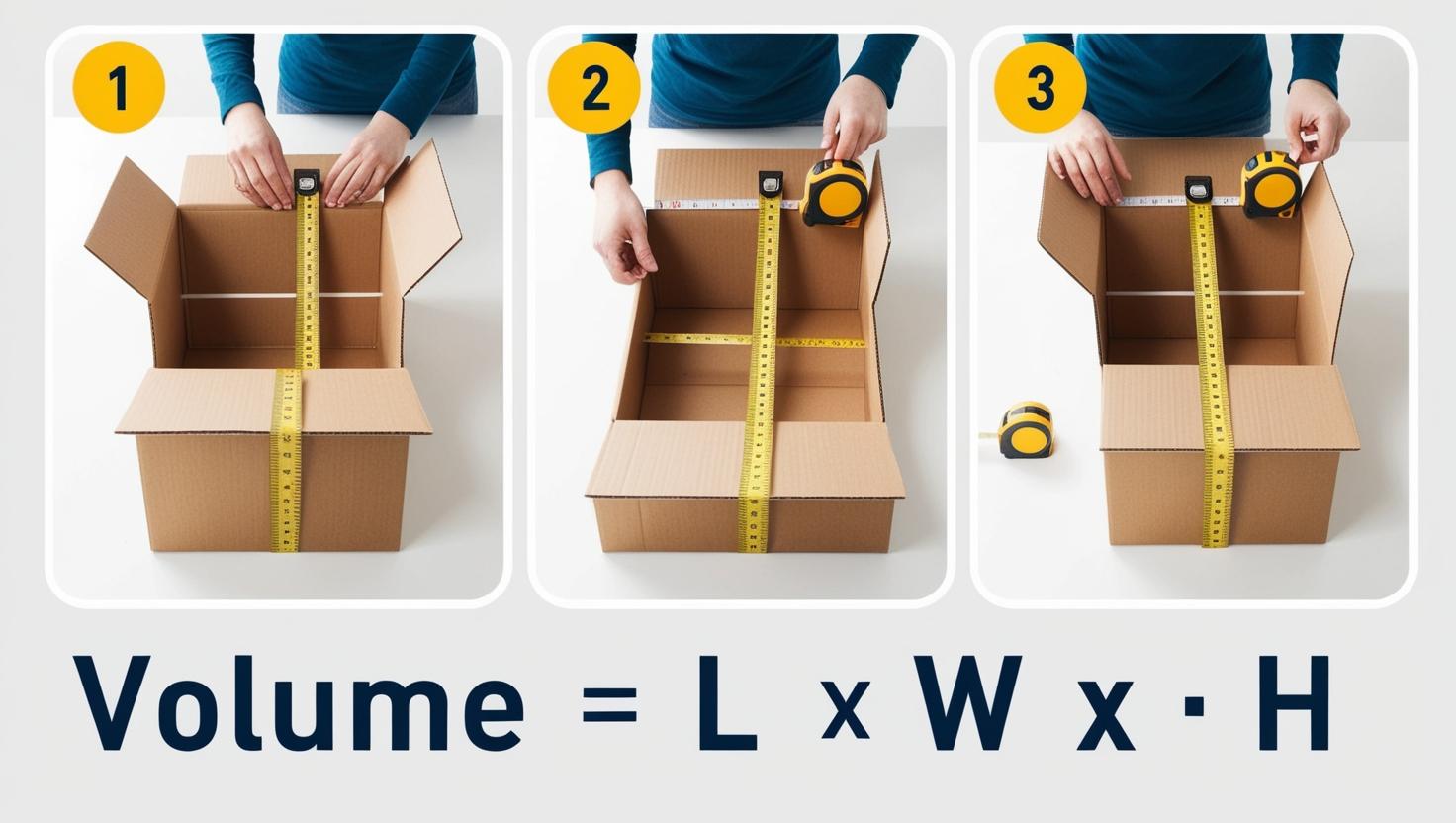

Here’s a simple method:

Step 1: Place the Box Correctly

Set it down in the position it will stand or be displayed in.

Step 2: Measure the Length

Find the longest side along the base.

Step 3: Measure the Width

This is the side perpendicular to the length, also along the base.

Step 4: Measure the Height

This is the vertical distance from the bottom to the top of the box.

Use a ruler or tape measure, and note whether you’re using inches, centimeters, or millimeters. If you’re providing measurements for a packaging order, always clarify whether your numbers are internal or external dimensions.

Internal vs External Dimensions

This is another source of confusion. What’s the difference?

- Internal dimensions refer to the space inside the box. Use these when you need a product to fit snugly inside.

- External dimensions refer to the outer measurements of the box, which matter for stacking and shipping.

When working with a packaging partner like Custom Packaging Pro, always clarify which you’re using. We’ll help you adjust for material thickness and ensure your product fits properly.

Why These Measurements Matter in Packaging

Understanding the length, width, and height of your packaging can save your business time, money, and product damage.

🚛 1. Accurate Shipping Costs

Carriers like UPS and FedEx use dimensional weight pricing. That means your shipping cost depends not only on actual weight but also on how much space your box takes up. A box that’s too large or inefficiently shaped can cost far more to ship.

📦 2. Better Product Protection

When a product fits snugly in its packaging, it moves less during transit. That reduces the risk of breakage or wear. If you guess the box size, you risk choosing something too tight or too loose.

🧊 3. Cooler Branding and Unboxing

Custom packaging is part of your brand. The right dimensions let you create packaging that’s elegant, compact, and memorable. Bulky or oversized boxes give a poor impression and waste material.

How Dimensional Weight is Calculated

Shipping companies often use this formula:

DIM weight = (Length × Width × Height) ÷ DIM factor

- Most U.S. carriers use a DIM factor of 139 (in inches).

- Round up your box measurements to the nearest inch before plugging them in.

📦 Example:

A box that’s 14″ × 10″ × 6″

→ Volume = 840 cubic inches

→ DIM weight = 840 ÷ 139 = ~6.04 lbs

Even if your product weighs 2 pounds, you’ll be charged for 6 pounds based on size.

That’s why getting the dimensions right — or optimizing your box design with Custom Packaging Pro — can lead to real savings.

Custom Packaging Pro’s Approach to Dimensions

We specialize in building packaging around your product — not the other way around.

Our process includes:

- Verifying your provided length, width, and height

- Creating packaging that fits your product with minimal waste

- Adjusting for thickness, strength, and shipping optimization

Whether you’re packaging electronics, beauty products, apparel, or food, we help you design boxes that are functional, affordable, and stunning.

FAQs: Quick Answers About Length, Width, and Height

Q1. What’s the standard way to write dimensions?

A: Always use Length × Width × Height (L × W × H) unless you’re told otherwise. This is the format used across packaging, shipping, and logistics.

Q2. How do I measure box dimensions correctly?

A: Place the box in its natural standing position. Measure the longest base side (length), the shorter base side (width), and the vertical side (height). Use a tape measure and write down your units.

Q3. Are internal dimensions more important than external ones?

A: It depends. If you’re ensuring product fit, use internal dimensions. If you’re calculating shipping or storage space, external dimensions matter more.

Q4. Can I use any unit of measurement?

A: Yes, but be consistent. Most U.S. packaging uses inches, while many international standards use millimeters or centimeters. Always confirm with your packaging supplier.

Q5. What happens if I get the dimensions wrong?

A: You could end up with boxes that don’t fit your product, higher shipping costs, or wasted storage space. Working with an experienced packaging company like Custom Packaging Pro reduces these risks.

Q6. Is depth the same as height?

A: Often, yes. In some industries, “depth” is used in place of “height.” Both refer to the vertical measurement. However, clarify which term your packaging partner uses to avoid mistakes.

Q7. How do I design a custom box with exact dimensions?

A: Provide your product measurements using length, width, and height. Share whether they are internal or external dimensions. Our design team at Custom Packaging Pro will handle the rest, including mockups and dielines.

Final Thoughts

The trio of length width height forms the foundation of smart packaging decisions. These measurements may seem simple, but they drive everything from design and printing to shipping and customer satisfaction.

Whether you’re launching a new product or optimizing an existing package, knowing your dimensions — and how to use them — sets you up for success.

At Custom Packaging Pro, we don’t just build boxes. We create smart, scalable solutions that fit your product and your business. Talk to our team today to get packaging that measures up — every time.